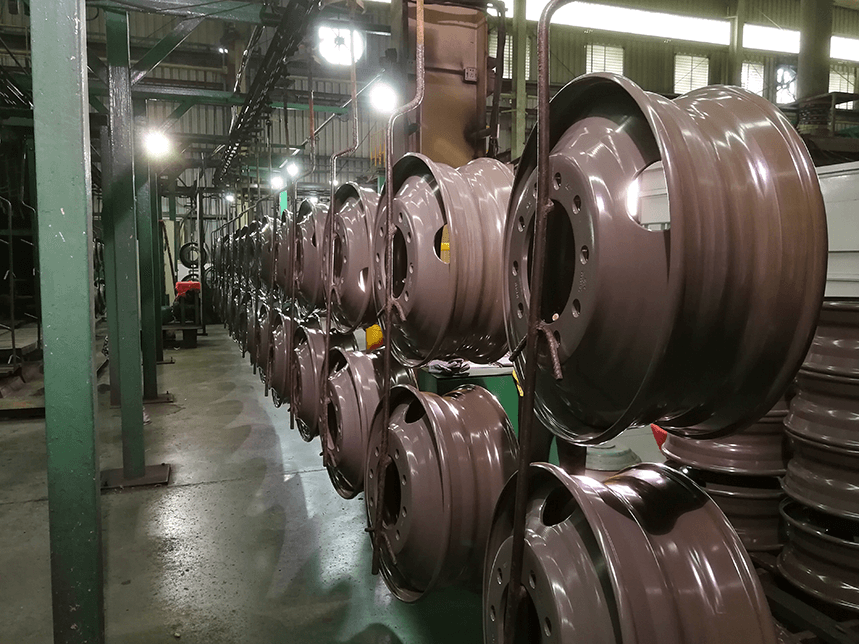

Amasondo wensimbi yensimbi aqinile futhi aqinile ayi-8.5-20 we-trailer encane

Idiski yediski isebenzisa ukwakheka kwelungelo lobunikazi lomumo "wesondo le-Bridge-Arc" ukuthuthukisa amandla nokulayisha umthamo, futhi kunciphise ukuhlukaniswa kwediski emgodini we-vent.

Idizayini yelungelo lobunikazi yeRidge ithuthukisa amandla erimu lesondo ngempumelelo.

Ukusetshenziswa kwamandla aphezulu wensimbi ekhethekile yamasondo nokuma kweBridge-arc, 20% wokunciphisa isisindo samasondo, ukukhuphula amandla ngo-12%.

Umklamo welungelo lobunikazi weBig Radian ku-flange uvimbela isondo ukuphuma erimeni lapho imoto ijika ngokucijile.

Isakhiwo esihlukile sesimo sabalandeli sithuthukisa ukushabalalisa ukushisa (isivivinyo sifakazele ukuthi izinga lokushisa kwesondo lesondo le-Bridge-arc lingaphansi ngama-2 degree kunalelo lesondo elijwayelekile, lapho izinga lokushisa kwethayi linciphisa i-1 degree lingenza isondo lisebenze ngaphezu kwamakhilomitha angama-5000 kuya kwayi-6000. Uma sisebenzisa isondo le-Bridge-arc, lingenza isondo ligijime ngaphezu kwamakhilomitha ayi-10 000.

Indlela yesondlo yensimbi yensimbi:

1. Lapho izinga lokushisa kwerimu lensimbi liphezulu, kufanele livunyelwe ukuthi lipholile ngokwemvelo ngaphambi kokuhlanzwa. Ungalokothi usebenzise amanzi abandayo ukuyihlanza. Ngaphandle kwalokho, irimu yensimbi ye-aluminium izokonakala, futhi nebhuleki disc izokhubazeka, okuzothinta ukubhuleka. Ngaphezu kwalokho, ukuhlanza irimu yensimbi ngensipho yokushisa ephezulu kuzodala ukusabela kwamakhemikhali ebusweni bendandatho yensimbi, kungcolise futhi kuthinte ukubukeka.

2. Lapho irimu yensimbi inamabala ne-asphalt okunzima ukuyisusa, uma i-ejenti yokuhlanza ingasizi, zama ukuyisusa ngebhulashi, kodwa ungasebenzisi ibhulashi eliqinile, ikakhulukazi ibhulashi lensimbi, ukuze kulimaze ubuso bomphetho wensimbi.

3. Uma indawo lapho imoto itholakala khona imanzi, irimu yensimbi kufanele ihlanzwe njalo ukugwema ukubola kasawoti ebusweni be-aluminium.

4. Uma kunesidingo, ngemuva kokuhlanzwa, irimu yensimbi ingathanjiswa ukuze kugcinwe kukhanya kuze kube phakade.

Amapharamitha womkhiqizo

|

Usayizi wesondo |

Usayizi weTire |

Uhlobo lwe-Bolt |

Umgodi ophakathi nendawo |

I-PCD |

I-Offset |

Ukujiya kwediski, okuguqulwayo) |

Okusondele. Wt. (kg) |

|

10.00-20 |

14.00R20 |

10,27 |

281 |

335 |

115.5 |

14 |

68 |

|

|

|

|

|

|

|

|

|

|

8.5-24 |

12.00R24 |

10,26 |

281 |

335 |

180 |

14/16 |

69 |

|

8.5-24 |

12.00R24 |

10,27 |

281 |

335 |

180 |

14/16 |

78 |

|

|

|

|

|

|

|

|

|

|

8.5-20 |

12.00R20 |

10,26 |

281 |

335 |

180 |

14/16 |

53 |

|

8.5-20 |

12.00R20 |

10,27 |

281 |

335 |

180 |

14/16 |

61 |

|

8.5-20 |

12.00R20 |

8,32 |

221 |

285 |

180 |

16 |

55 |

|

8.5-20 |

12.00R20 |

10,32 |

222 |

285.75 |

180 |

16 |

55 |

|

|

|

|

|

|

|

|

|

|

8.00-20 |

11.00R20 |

10,26 |

281 |

335 |

175 |

14 |

50 |

|

8.00-20 |

11.00R20 |

10,27 |

281 |

335 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

8,32 |

221 |

285 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

10,32 |

222 |

285.75 |

175 |

14/16 |

53 |

|

|

|

|

|

|

|

|

|

|

7.50V-20 |

10.00R20 |

10,26 |

281 |

335 |

165 |

13/14 |

47 |

|

7.50V-20 |

10.00R20 |

10,27 |

281 |

335 |

165 |

14/16 |

47 |

|

7.50V-20 |

10.00R20 |

8,32 |

221 |

285 |

165 |

14/16 |

50 |

|

7.50V-20 |

10.00R20 |

8,32 |

214 |

275 |

165 |

14 |

47 |

|

7.50V-20 |

10.00R20 |

10,32 |

222 |

285.75 |

165 |

14/16 |

50 |

|

|

|

|

|

|

|

|

|

|

7.25-20 |

10.00R20 |

8,32 |

221 |

285 |

158 |

13 |

49 |

|

|

|

|

|

|

|

|

|

|

7.00T-20 |

9.00R20 |

8,32 |

221 |

285 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

8,32 |

214 |

275 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

10,32 |

222 |

285.75 |

160 |

13/14 |

40 |

|

|

|

|

|

|

|

|

|

|

6.5-20 |

8.25R20 |

6,32 |

164 |

222.25 |

135 |

12 |

39 |

|

6.5-20 |

8.25R20 |

8,32 |

214 |

275 |

135 |

12 |

38 |

|

6.5-20 |

8.25R20 |

8,27 |

221 |

275 |

135 |

12 |

38 |

|

|

|

|

|

|

|

|

|

|

6.5-16 |

8.25R16 |

6,32 |

164 |

222.25 |

135 |

10 |

26 |

|

|

|

|

|

|

|

|

|

|

6.00G-16 |

7.5R16 |

6,32 |

164 |

222.25 |

135 |

10 |

22.5 |

|

6.00G-16 |

7.5R16 |

5,32 |

150 |

208 |

135 |

10 |

23 |

|

|

|

|

|

|

|

|

|

|

5.50F-16 |

6.5-16 |

6,32 |

164 |

222.25 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

150 |

208 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,29 |

146 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

133 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

6,15 |

107 |

139.7 |

0 |

5 |

16 |

|

5.50F-16 |

6.5-16 |

5,17.5 |

107 |

139.7 |

0 |

5 |

16 |

|

|

|

|

|

|

|

|

|

|

5.50-15 |

6.5-15 |

5,29 |

146 |

203.2 |

115 |

8 |

16 |

Imibuzo evame ukubuzwa

Q1. Yini imigomo yakho ukupakisha?

IMP: Ngokuvamile, izimpahla zivalwa ezikhwameni zobuqili futhi zigcwele amabhokisi namaphara noma amacala enkuni.

Q2. Yini imigomo yakho yokukhokha?

A: T / T (idiphozi + esele ngaphambi kokulethwa). Sizokukhombisa izithombe zemikhiqizo namaphakeji ngaphambi kokukhokha ibhalansi.

Q3. Yini imigomo yakho yokulethwa?

A: I-EXW, i-FOB, i-CFR, i-CIF.

Q4. Kuthiwani ngesikhathi sakho sokulethwa?

A: Ngokuvamile, kuzothatha izinsuku ezingama-25 kuya kwezingama-60 ngemuva kokuthola inkokhelo yakho kusengaphambili. Isikhathi esithile sokulethwa sincike ezintweni nobuningi be-oda lakho.

Q5. Ingabe ukukhiqiza ngokuvumelana amasampula?

A: Yebo, singakhiqiza ngamasampuli akho noma imidwebo yobuchwepheshe. Singakha isikhunta nezinsiza.

Q6. Iyini inqubomgomo yakho yesampula?

A: Singakunika isampula mahhala uma sinezingxenye ezilungile esitokweni, kepha amakhasimende kufanele akhokhe izindleko zeposi.

Q7. Wenza kanjani ibhizinisi lethu libe nobudlelwano besikhathi eside nobuhle?

A: Sinikeza amaklayenti ethu insiza yokumisa esisodwa, kusuka entweni ethile kuya emikhiqizweni yokugcina ehlanganisiwe, ukuxazulula izinkinga ezahlukahlukene kumakhasimende ahlukahlukene emhlabeni wonke.