3 PC 8.5-24 Heavy Duty Truck Amasondo

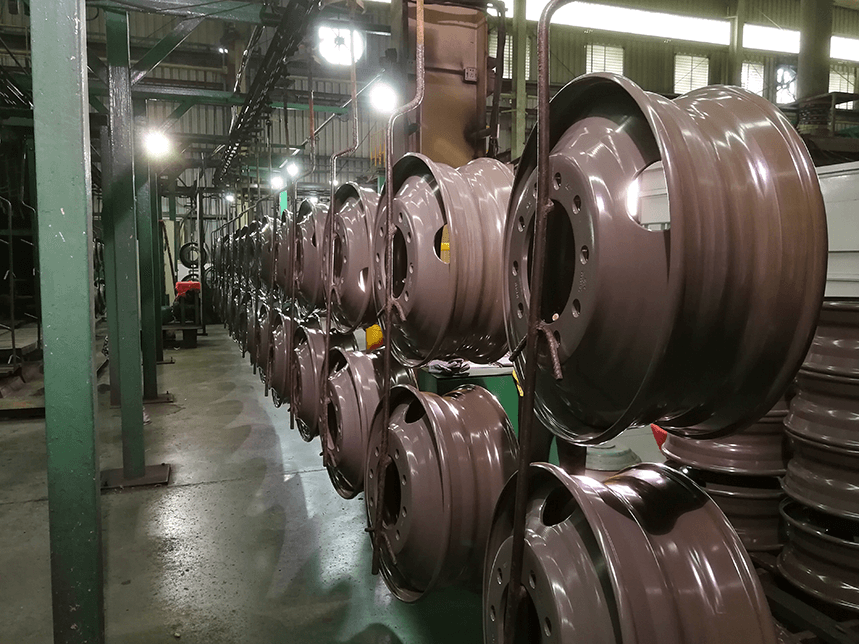

Idizayini eyodwa ye-patent enkulu ye-flange enkulu, isusa ingozi efihliwe yokuqhuma kwesondo.

I-2.Flange angle iyashintsha ukusuka mpo kuye nxazonke-radian, kunciphisa ukungqubuzana, futhi kunciphise ukukhiqizwa kokushisa.

I-3.Bigger ne-flange enkulu yenza isondo lakho limelane nengcindezi eyengeziwe.

4.Patent design of usebe ebanzi, ukukhulula ingcindezi isondo.

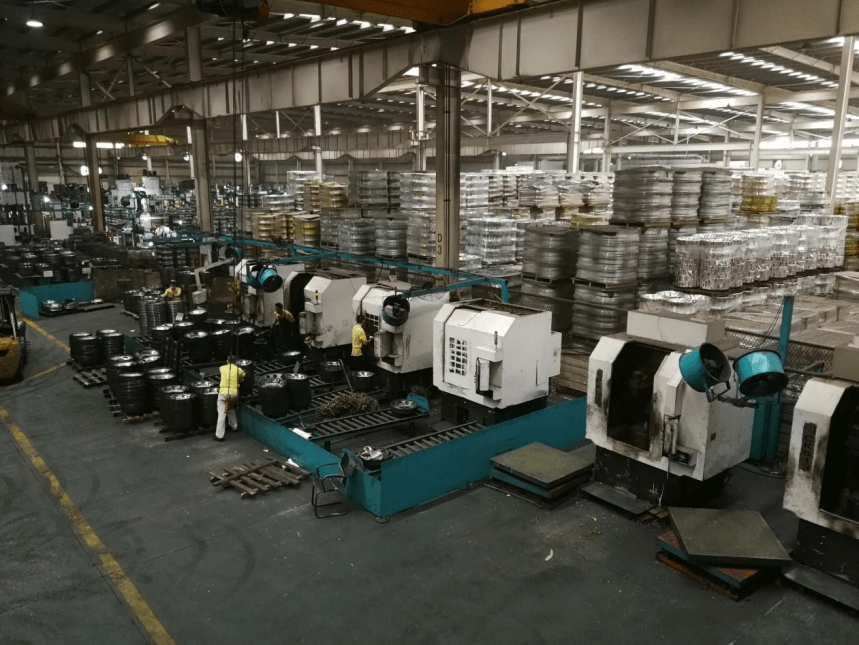

Ama-technics we-5.Spinning enza impilo ende yediski kunezobuchwepheshe obujwayelekile bokushaya.

Nge-microscope, ubuchwepheshe bokuphotha obenza isakhiwo se-athomu sensimbi singacekelwa phansi.

Nge-microscope, ukusunduza ubuchwepheshe okwenza ukwakheka kwe-athomu lensimbi kubhujiswe futhi kuqhume imifantu.

Izinzuzo aluminium ingxubevange steel usebe:

1. Ukonga amandla, ukushabalalisa okuhle kokushisa. Ukusetshenziswa kwe-aluminium alloy steel rim kunganciphisa isisindo sayo yonke imoto, kunciphise i-inertia yokujikeleza kwamasondo, kuthuthukise ukusebenza kwejubane lemoto, kunciphise isidingo samandla okubhaka amabhuleki, ukwehlisa ukusetshenziswa kwephethiloli.

2. Ukuphepha okuphezulu. Ezimotweni ezihamba ngesivinini esikhulu, ukwehla kokushisa kwesondo eliphakeme kanye nokuncipha kokusebenza kahle kwamabhuleki okubangelwe ukuqubuzana kokufika kwamasondo nokubhola amabhuleki kuvamile. I-coefficient of conduction coefficient ye-aluminium alloy iphindwe kathathu kunensimbi nensimbi, ngakho-ke kulula ukusabalalisa ukushisa okwenziwe ngamathayi kanye ne-chassis emoyeni. Ngisho nasendabeni yokushayela ngejubane elide noma ukubopha amabhuleki okuqhubekayo emgwaqeni owehlayo, ingagcina imoto kushisa okufanele futhi yehlise izinga lokuqhuma kwesondo.

3. Amandla aphakeme kakhulu. Amandla wokuthwala we-aluminium alloy steel rim aphindwe kahlanu kunalawo ojwayelekile wensimbi. Isondo elihlanganisiwe likhubazeka kuphela u-5cm ngemuva kokuthwala u-71200kg. Ngamanye amagama, amandla erimu ye-aluminium alloy iphindwe kahlanu kunerimu yensimbi.

4. Ukubukeka okuhle. Ukufudumala nokungezwani kwe-aluminium ingxubevange ekushiseni okuphezulu ketshezi kungcono kunaleyo yensimbi yensimbi, futhi inqubo yokupholisha neyokuqothula kamuva ingayenza ibe yinhle futhi iguquke; ukwelashwa kwendawo yokulwa nokugqwala kanye ne-electrostatic powder coating nayo iyenze ibe yinde njengokusha.

Amapharamitha womkhiqizo

|

Usayizi wesondo |

Usayizi weTire |

Uhlobo lwe-Bolt |

Umgodi ophakathi nendawo |

I-PCD |

I-Offset |

Ukujiya kwediski, okuguqulwayo) |

Okusondele. Wt. (kg) |

|

10.00-20 |

14.00R20 |

10,27 |

281 |

335 |

115.5 |

14 |

68 |

|

|

|

|

|

|

|

|

|

|

8.5-24 |

12.00R24 |

10,26 |

281 |

335 |

180 |

14/16 |

69 |

|

8.5-24 |

12.00R24 |

10,27 |

281 |

335 |

180 |

14/16 |

78 |

|

|

|

|

|

|

|

|

|

|

8.5-20 |

12.00R20 |

10,26 |

281 |

335 |

180 |

14/16 |

53 |

|

8.5-20 |

12.00R20 |

10,27 |

281 |

335 |

180 |

14/16 |

61 |

|

8.5-20 |

12.00R20 |

8,32 |

221 |

285 |

180 |

16 |

55 |

|

8.5-20 |

12.00R20 |

10,32 |

222 |

285.75 |

180 |

16 |

55 |

|

|

|

|

|

|

|

|

|

|

8.00-20 |

11.00R20 |

10,26 |

281 |

335 |

175 |

14 |

50 |

|

8.00-20 |

11.00R20 |

10,27 |

281 |

335 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

8,32 |

221 |

285 |

175 |

14/16 |

53 |

|

8.00-20 |

11.00R20 |

10,32 |

222 |

285.75 |

175 |

14/16 |

53 |

|

|

|

|

|

|

|

|

|

|

7.50V-20 |

10.00R20 |

10,26 |

281 |

335 |

165 |

13/14 |

47 |

|

7.50V-20 |

10.00R20 |

10,27 |

281 |

335 |

165 |

14/16 |

47 |

|

7.50V-20 |

10.00R20 |

8,32 |

221 |

285 |

165 |

14/16 |

50 |

|

7.50V-20 |

10.00R20 |

8,32 |

214 |

275 |

165 |

14 |

47 |

|

7.50V-20 |

10.00R20 |

10,32 |

222 |

285.75 |

165 |

14/16 |

50 |

|

|

|

|

|

|

|

|

|

|

7.25-20 |

10.00R20 |

8,32 |

221 |

285 |

158 |

13 |

49 |

|

|

|

|

|

|

|

|

|

|

7.00T-20 |

9.00R20 |

8,32 |

221 |

285 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

8,32 |

214 |

275 |

160 |

13 |

40 |

|

7.00T-20 |

9.00R20 |

10,32 |

222 |

285.75 |

160 |

13/14 |

40 |

|

|

|

|

|

|

|

|

|

|

6.5-20 |

8.25R20 |

6,32 |

164 |

222.25 |

135 |

12 |

39 |

|

6.5-20 |

8.25R20 |

8,32 |

214 |

275 |

135 |

12 |

38 |

|

6.5-20 |

8.25R20 |

8,27 |

221 |

275 |

135 |

12 |

38 |

|

|

|

|

|

|

|

|

|

|

6.5-16 |

8.25R16 |

6,32 |

164 |

222.25 |

135 |

10 |

26 |

|

|

|

|

|

|

|

|

|

|

6.00G-16 |

7.5R16 |

6,32 |

164 |

222.25 |

135 |

10 |

22.5 |

|

6.00G-16 |

7.5R16 |

5,32 |

150 |

208 |

135 |

10 |

23 |

|

|

|

|

|

|

|

|

|

|

5.50F-16 |

6.5-16 |

6,32 |

164 |

222.25 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

150 |

208 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,29 |

146 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

5,32 |

133 |

203.2 |

115 |

10 |

18 |

|

5.50F-16 |

6.5-16 |

6,15 |

107 |

139.7 |

0 |

5 |

16 |

|

5.50F-16 |

6.5-16 |

5,17.5 |

107 |

139.7 |

0 |

5 |

16 |

|

|

|

|

|

|

|

|

|

|

5.50-15 |

6.5-15 |

5,29 |

146 |

203.2 |

115 |

8 |

16 |

Imibuzo evame ukubuzwa

Q1. Yini imigomo yakho ukupakisha?

IMP: Ngokuvamile, izimpahla zivalwa ezikhwameni zobuqili futhi zigcwele amabhokisi namaphara noma amacala enkuni.

Q2. Yini imigomo yakho yokukhokha?

A: T / T (idiphozi + esele ngaphambi kokulethwa). Sizokukhombisa izithombe zemikhiqizo namaphakeji ngaphambi kokukhokha ibhalansi.

Q3. Yini imigomo yakho yokulethwa?

A: I-EXW, i-FOB, i-CFR, i-CIF.

Q4. Kuthiwani ngesikhathi sakho sokulethwa?

A: Ngokuvamile, kuzothatha izinsuku ezingama-25 kuya kwezingama-60 ngemuva kokuthola inkokhelo yakho kusengaphambili. Isikhathi esithile sokulethwa sincike ezintweni nobuningi be-oda lakho.

Q5. Ingabe ukukhiqiza ngokuvumelana amasampula?

A: Yebo, singakhiqiza ngamasampuli akho noma imidwebo yobuchwepheshe. Singakha isikhunta nezinsiza.

Q6. Iyini inqubomgomo yakho yesampula?

A: Singakunika isampula mahhala uma sinezingxenye ezilungile esitokweni, kepha amakhasimende kufanele akhokhe izindleko zeposi.

Q7. Wenza kanjani ibhizinisi lethu libe nobudlelwano besikhathi eside nobuhle?

A: Sinikeza amaklayenti ethu insiza yokumisa esisodwa, kusuka entweni ethile kuya emikhiqizweni yokugcina ehlanganisiwe, ukuxazulula izinkinga ezahlukahlukene kumakhasimende ahlukahlukene emhlabeni wonke.